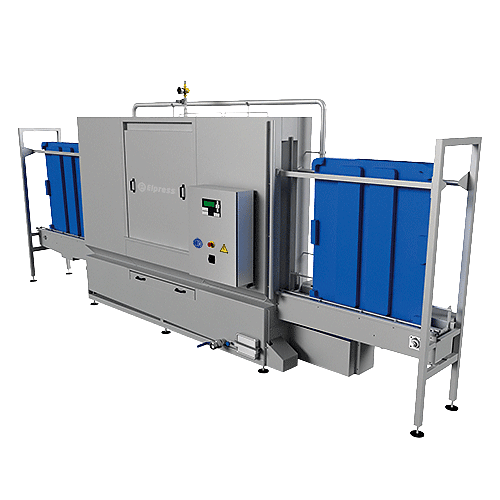

ENW-5000 – Norm Bin Washer Tunnel

Euro Bin Washing System Elpress ENW-5000

Capacity: max. 60 standard euro bins per hour

Main wash and rinse zone

The ENW-5000 norm bin washer tunnel is a high-capacity solution for food factories requiring continuous cleaning. It processes up to 50 Euro bins per hour, making it ideal for large production environments. Built from stainless steel and equipped with main wash and rinse zones, the ENW-5000 ensures compliance with HACCP and BRCGS hygiene standards.

AES Food Equipment are UK’s main distributors for Elpress Hygiene Equipment

- Fast Delivery

- Expert Advice

- Exclusive Deals

Features & Benefits

- Capacity: washes up to 50 Euro bins per hour

- Stainless steel SS304 construction for durability and hygiene

- Tunnel design supports continuous cleaning operations

- Main wash and rinse zones for thorough cleaning

- Adjustable settings for different soil levels

- Reliable performance in high-volume environments

Technical Specs

| Specification | Value |

| Article Number | 83103250 |

| Capacity | 50 bins/hour |

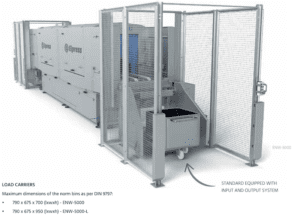

| Compatible Bin Sizes | 200 L and 300 L Euro bins (DIN 9797) |

| Voltage / VAC | 3×400 |

| Frequency / Hz | 50 |

| Power / kW | Depending on configuration |

| Water Consumption | Per datasheet |

| Wash Zones | Main wash + rinse |

| Construction | Stainless steel SS304 |

BIN WASHERS WITH AN EYE FOR DETAIL

Elpress bin washers ensure the complete and effective washing of your bins. Depending on how dirty they are, the wash program can be set up to a maximum of 30 minutes. The process in the bin washer consists of the main wash program and a rinse program which rinses out the bin and removes detergent. At the end of the process, the bins are removed from the machine again. The advantages of the Elpress bin washers:

- Low energy consumption

- Simple operation

- Removable filter drawer

- Complete spray range

- Rinse program with clean water

- Made from stainless steel 304

- Selectable wash program

Why Choose This Model

- Tailored for oversized Euro bin washing requirements

- Supports high-throughput production environments

- Tunnel design reduces labour costs with automated handling

- AES provides UK-wide installation and servicing

Options & Accessories

- Pre-wash zone for heavily soiled large bins

- Dosing pump for detergent accuracy

- Steam extraction for safe vapour removal

- Heating options: hot water coil, steam, or electric element

- Custom feed systems for large-bin handling integration

FAQ's

The ENW-5000 can wash up to 50 Euro bins per hour in continuous operation.

It is designed for 200 L and 300 L Euro bins that comply with DIN 9797 standards.

Yes, the ENW-5000 includes main wash and rinse zones, with pre-wash available as an option.

Yes, its tunnel design makes it ideal for high-volume environments needing continuous cleaning.

Yes, AES Food Equipment provides installation, training, and after-sales support across the UK.

Delivery & lead times

We do our best to deliver within the lead times listed above. Although if you have any specific requests, please get in touch and we can see what we can do.

For international shipping, lead times may vary.

international shipping