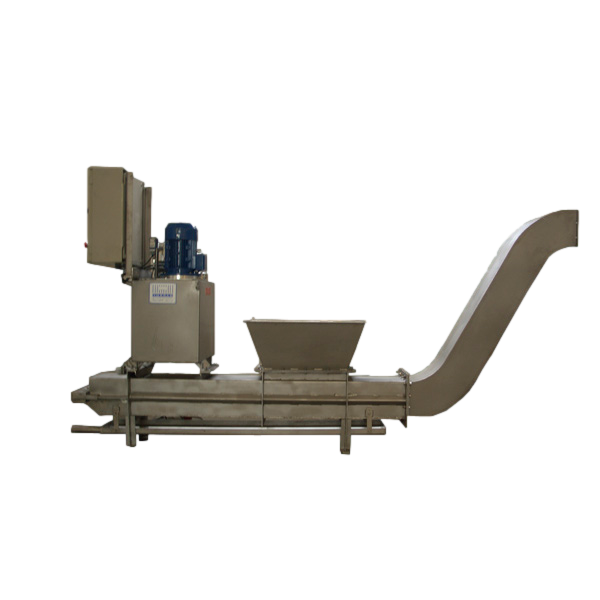

Hubert Haas Combined Pig Scalder and Dehairer Machine for Pigs

The Hubert Haas Combined Scalder and Dehairer Machine for Pigs is designed for efficiency and reliability in pork meat processing operations. It integrates scalding and dehairing into one smooth process, enhancing productivity. Built to last, this machine offers consistent performance, meeting the demands of small volume pork processing with ease. It’s engineered for optimal hygiene standards, ensuring clean and precise results. Ideal for businesses looking to streamline their hog / pork preparation process with a focus on quality and time-saving operations.

Standard Features

- 2 roller system for thorough depilation

- Head scratcher also for the difficult to access head area

- Mobile on 4 castors

- Newly developed, reinforced transmission

- Special rubber racket (also on the back wall)

- Electric heating in an oil bath

- Integrated control and operating unit in the machine housing

- Swing-out rollers for cleaning the machine

AES Food Equipment are the UK & Irelands exclusive distributor for Hubert Haas Pig Slaughtering Equipment